In the manufacturing industry, even the minutest details can have a substantial impact on the overall quality and durability of a product. Wooden pallets, extensively utilized for shipping and storage, are no exception to this rule. Recent research has unveiled an interesting correlation between the choice of nails and the lifespan of wooden pallets. By carefully selecting the appropriate type of nails, manufacturers can significantly improve the durability of their pallets, subsequently distinguishing themselves from their competitors in the highly competitive market.

The difference in nail selection during the assembly process of wooden pallets can result in a staggering ten-fold variation in their longevity when subjected to rough shipping conditions. This revelation underscores the significance of considering nails as a low-cost yet critical tool in manufacturing high-quality pallets. Ignoring the importance of nail type in pallet construction can potentially lead to subpar products that fail to meet customer expectations and impact a company’s reputation.

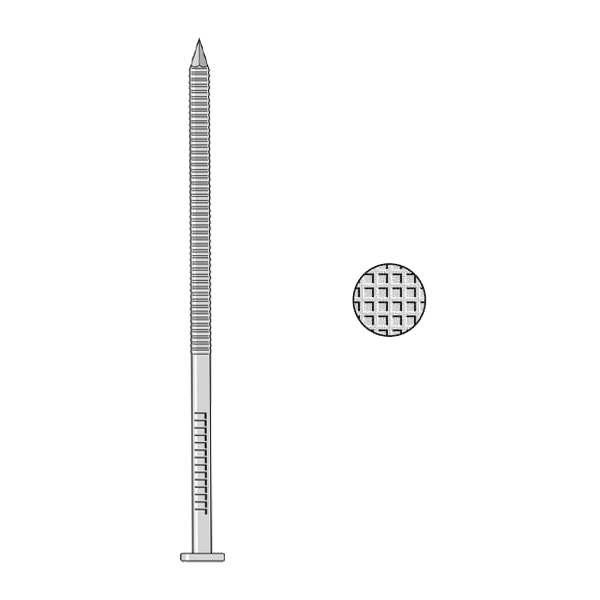

When determining the suitable nail type, the characteristics of the wood used in pallet construction must be taken into account. For low-density wood or softwood, using ring nails is highly recommended due to their superior pullout force. These nails firmly secure the wood and prevent it from loosening or becoming displaced during the demanding shipping process. On the other hand, medium or high-density wood necessitates the utilization of threaded nails. These nails, possessing the same thickness and thread, offer enhanced bending resistance, making them an ideal choice for such wood types.

Moreover, making informed decisions regarding nails can offer several advantages to wooden pallet manufacturers. Firstly, it ensures the durability and longevity of the pallets, ultimately leading to higher customer satisfaction. Customers will perceive the value and appreciate the robustness of pallets that can withstand the rigors of transportation and storage without succumbing to damage. Such reliability can create a competitive edge in the market, attracting more customers and potentially increasing sales and revenue.

Secondly, selecting appropriate nail types in manufacturing processes aligns with the guidelines set forth by search engines like Google. Complying with their crawling rules and search engine optimization practices ensures that manufacturers gain better visibility in online searches. This exposure can generate increased brand recognition, attracting potential customers within the digital landscape.

To conclude, the seemingly inconsequential choice of nails in the manufacturing of wooden pallets carries far-reaching consequences for their quality and longevity. By meticulously selecting the right nail type based on wood density, manufacturers can significantly improve their products and stand out from their competitors. This low-cost method has the potential to yield substantial benefits, including the creation of durable pallets that satisfy customer expectations and enhanced online visibility. Thus, it is imperative for wooden pallet manufacturers to acknowledge and prioritize the importance of nail selection in their production processes.

Post time: Sep-12-2023