Hardness Masonry and Concrete Building Nails

Application

Concrete nails find widespread application in the construction industry. Whether you are working on residential projects, commercial buildings, or even outdoor landscaping, these nails are a reliable option. They are typically used for securing wooden structures, ceramic tiles, drywall, and other materials to concrete surfaces. With their exceptional strength, concrete nails provide a secure and solid foundation for any construction project, ensuring long-lasting results.

Feature

1. Hard stainless steel: Constructed from premium stainless steel, these nails are extremely durable and resistant to rust and corrosion. This feature makes them perfect for applications in humid or outdoor environments, where other fasteners may falter.

2. Versatility: Concrete nails are compatible with a variety of materials, including wood, ceramics, and drywall. This versatility allows them to be used in a wide range of construction applications, making them an invaluable asset to contractors and builders.

3. Easy installation: Concrete nails are designed to be easily hammered into concrete surfaces with minimal effort. Their pointed tips and durable construction enable quick and efficient installation, saving both time and energy during the construction process.

4. Superior holding power: Due to their hardened steel composition, concrete nails offer exceptional holding power. Once properly secured in concrete, these nails provide a strong and secure attachment, minimizing the risk of any dislodging or loosening over time.

5. Cost-effective: Concrete nails are an affordable solution for construction projects, providing a high-quality alternative to other fastening methods. Moreover, their durability ensures long-term performance, saving money on potential replacements or repairs in the future.

Material Constituents

|

Sus |

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

Cu |

|

304 |

0.08 |

1.00 |

2.00 |

0.045 |

0.027 |

8.0-10.5 |

18.0-20.0 |

0.75 |

0.75 |

|

304Hc |

0.08 |

1.00 |

2.00 |

0.045 |

0.028 |

8.5-10.5 |

17.0-19.0 |

|

2.0-3.0 |

|

316 |

0.08 |

1.00 |

2.00 |

0.045 |

0.029 |

10.0-14.0 |

16.0-18.0 |

2.0-3.0 |

0.75 |

|

430 |

0.12 |

0.75 |

1.00 |

0.040 |

0.030 |

|

16.0-18.0 |

|

Wire Brands for Different Country

|

mm |

CN.W.G |

S.W.G |

B.W.G |

AS.W.G |

|

1G |

|

|

7.52 |

7.19 |

|

2G |

|

|

7.21 |

6.67 |

|

3G |

|

|

6.58 |

6.19 |

|

4G |

|

|

6.05 |

5.72 |

|

5G |

|

|

5.59 |

5.26 |

|

6G |

5.00 |

4.88 |

5.16 |

4.88 |

|

7G |

4.50 |

4.47 |

4.57 |

4.50 |

|

8G |

4.10 |

4.06 |

4.19 |

4.12 |

|

9G |

3.70 |

3.66 |

3.76 |

3.77 |

|

10G |

3.40 |

3.25 |

3.40 |

3.43 |

|

11G |

3.10 |

2.95 |

2.05 |

3.06 |

|

12G |

2.80 |

2.64 |

2.77 |

2.68 |

|

13G |

2.50 |

2.34 |

2.41 |

2.32 |

|

14G |

2.00 |

2.03 |

2.11 |

2.03 |

|

15G |

1.80 |

1.83 |

1.83 |

1.83 |

|

16G |

1.60 |

1.63 |

1.65 |

1.58 |

|

17G |

1.40 |

1.42 |

1.47 |

1.37 |

|

18G |

1.20 |

1.22 |

1.25 |

1.21 |

|

19G |

1.10 |

1.02 |

1.07 |

1.04 |

|

20G |

1.00 |

0.91 |

0.89 |

0.88 |

|

21G |

0.90 |

0.81 |

0.81 |

0.81 |

|

22G |

|

0.71 |

0.71 |

0.73 |

|

23G |

|

0.61 |

0.63 |

0.66 |

|

24G |

|

0.56 |

0.56 |

0.58 |

|

25G |

|

0.51 |

0.51 |

0.52 |

Custom Design Nails

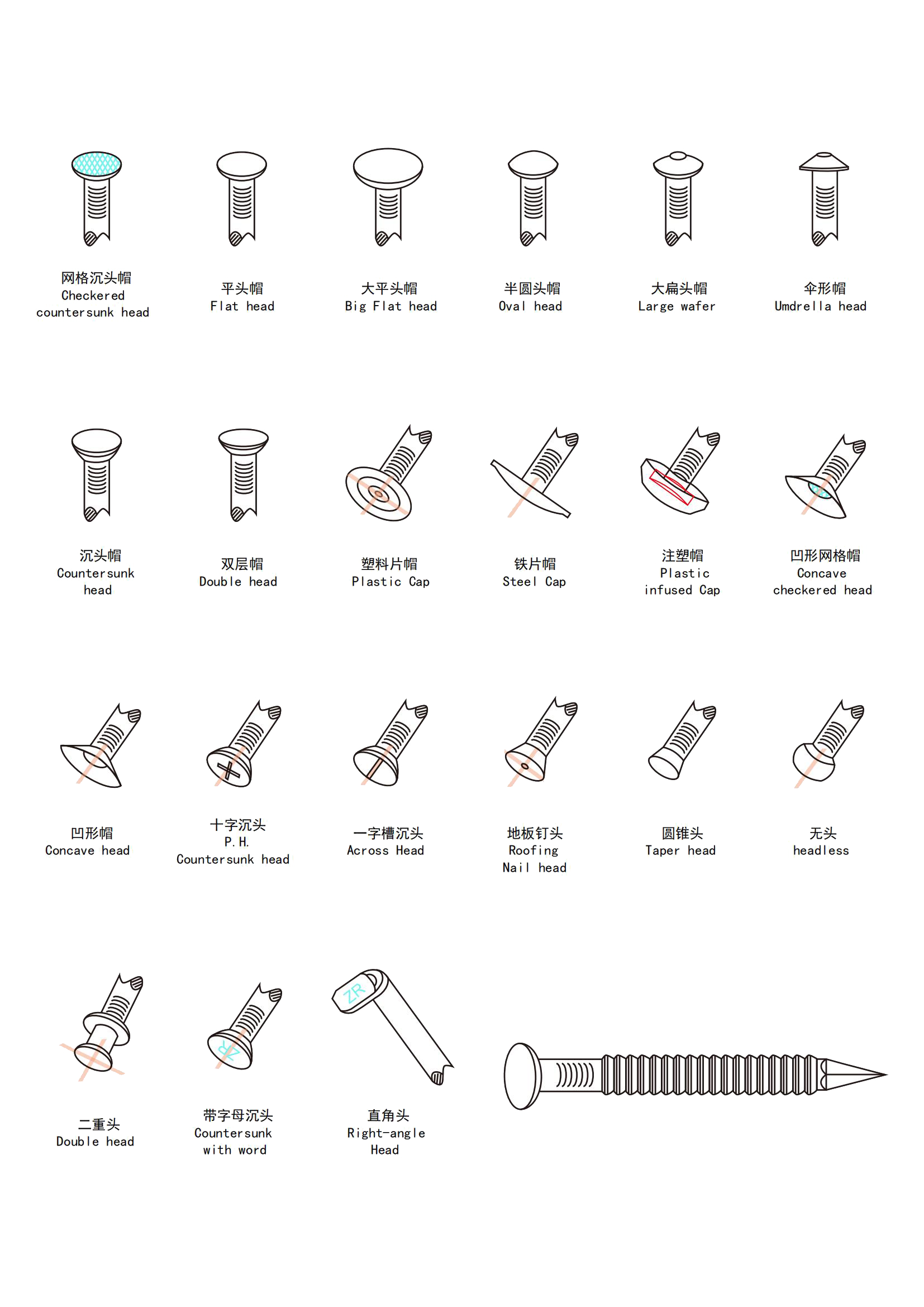

Type and Shape of Nails Head

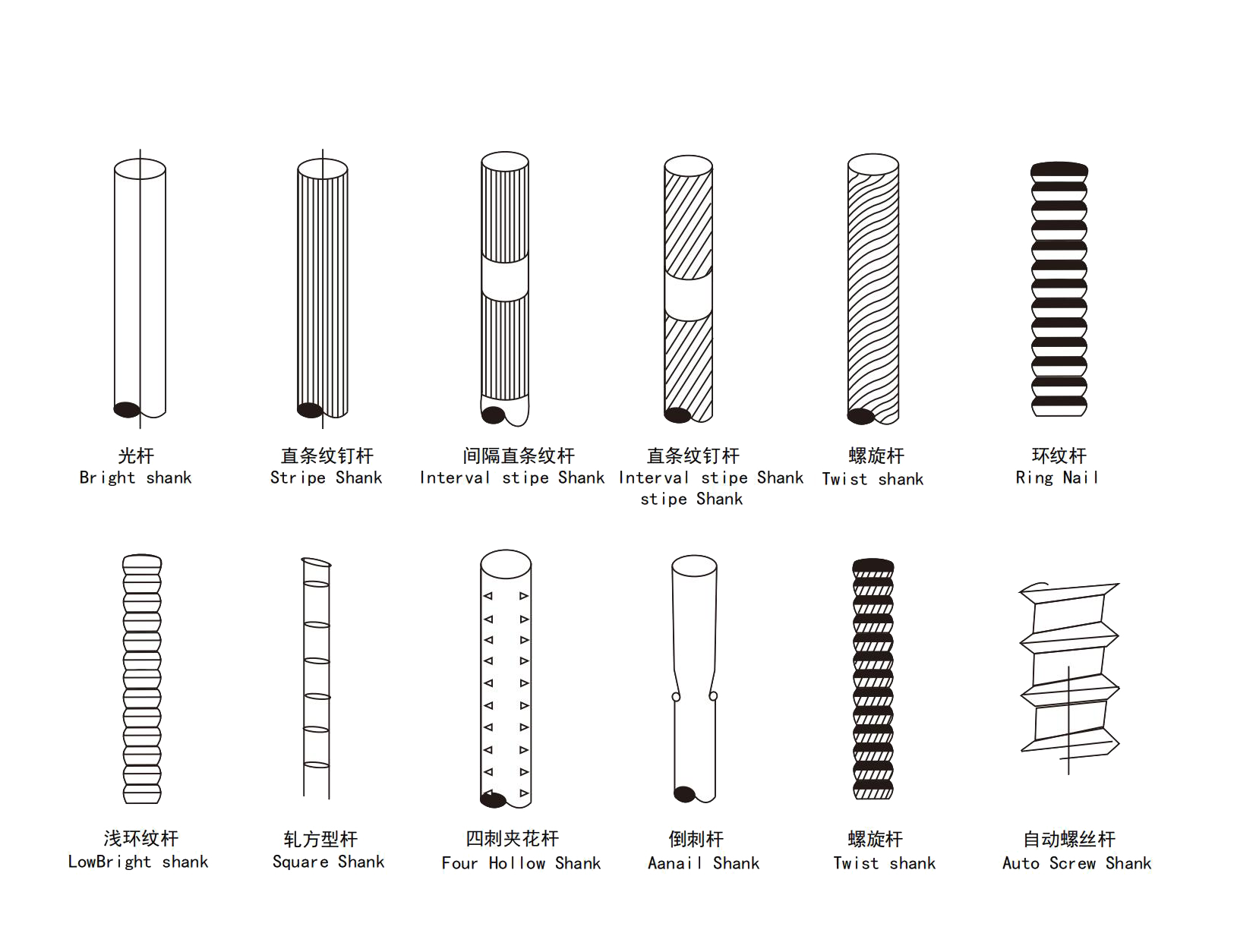

Type and Shape of Nails Shank

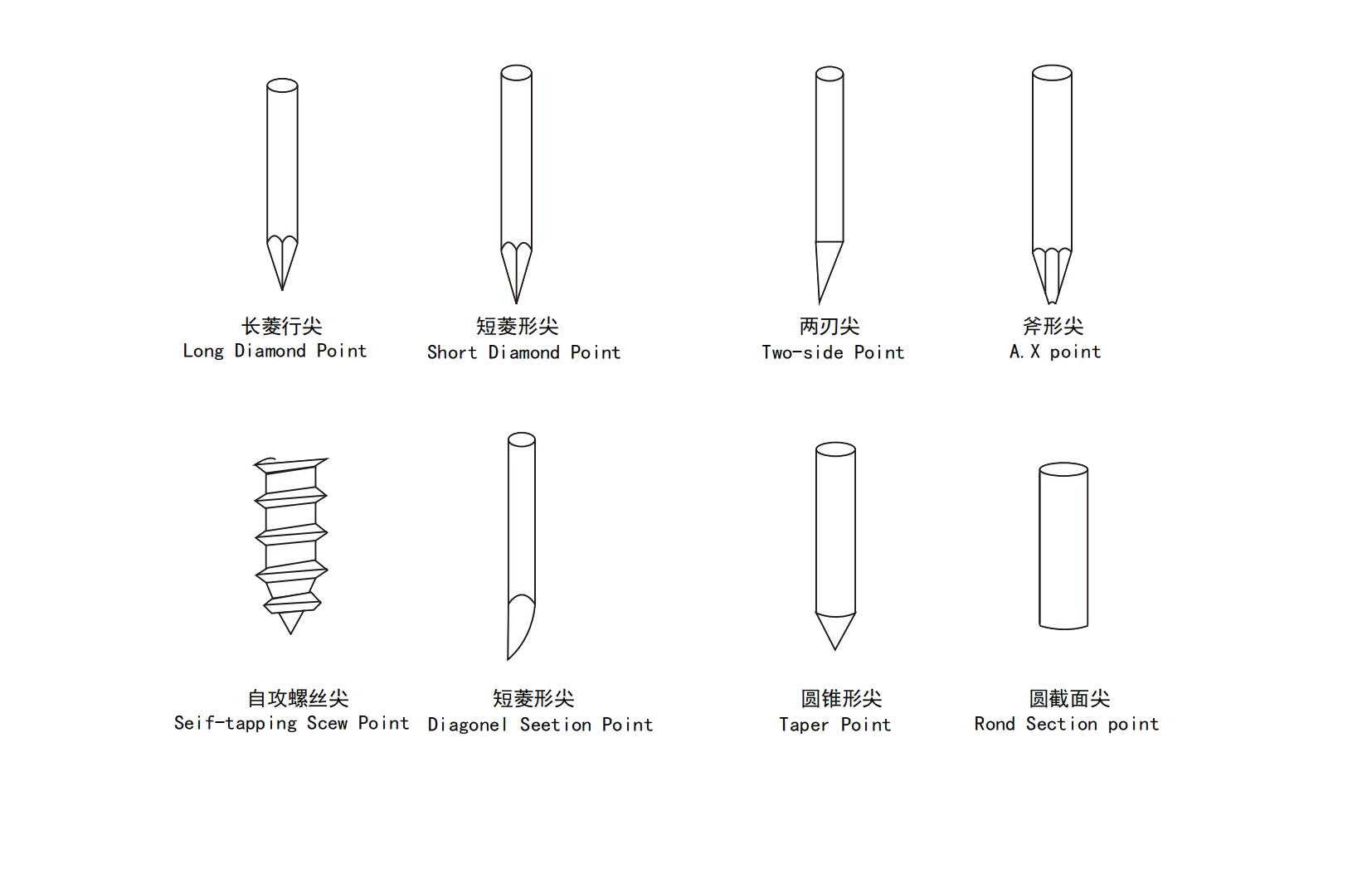

Type and Shape of Nails Point