Flat Head Copper Roofing Nails

Application

Copper roofing nails are primarily used for affixing copper roofing materials, including copper shingles, copper panels, and copper sheets, to ensure a secure and long-lasting installation. These nails provide a reliable solution for both residential and commercial roofing projects. Additionally, copper roofing nails can also be used in other applications where the combination of durability and aesthetic appeal is desired, such as for decorative purposes or woodworking projects.

Feature

1. High-Quality Copper: Copper roofing nails are constructed using premium-quality copper, which provides exceptional durability and resistance to rust, corrosion, and weathering. This ensures that the nails will maintain their strength even in the face of heavy rain, snow, or extreme temperatures.

2. Sharp and Pointed Tips: The nails feature sharp and pointed tips, allowing for easy and precise insertion into the roofing material. This makes the installation process smooth and efficient, reducing the risk of slipping or causing damage to the roof.

3. Wide Range of Lengths: Copper roofing nails are available in a variety of lengths to accommodate different roofing thicknesses and materials. Whether you're working on a small residential project or a large commercial building, you can find the perfect length to suit your needs.

4. Serrated or Smooth Shank: Copper roofing nails offer options for both serrated and smooth shank designs. The serrated shank provides enhanced grip and prevents the nails from loosening over time, ensuring a secure and long-lasting roof installation. On the other hand, smooth shank nails are suitable for applications where particular aesthetic requirements or specific building codes are necessary.

5. Aesthetic Appeal: Apart from their exceptional functional properties, copper roofing nails also add aesthetic charm to your building. The beautiful patina that develops over time on copper adds to the overall charm of a copper roof, adding a touch of elegance and sophistication to any structure.

Material Constituents

|

Sus |

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

Cu |

|

304 |

0.08 |

1.00 |

2.00 |

0.045 |

0.027 |

8.0-10.5 |

18.0-20.0 |

0.75 |

0.75 |

|

304Hc |

0.08 |

1.00 |

2.00 |

0.045 |

0.028 |

8.5-10.5 |

17.0-19.0 |

|

2.0-3.0 |

|

316 |

0.08 |

1.00 |

2.00 |

0.045 |

0.029 |

10.0-14.0 |

16.0-18.0 |

2.0-3.0 |

0.75 |

|

430 |

0.12 |

0.75 |

1.00 |

0.040 |

0.030 |

|

16.0-18.0 |

|

Wire Brands for Different Country

|

mm |

CN.W.G |

S.W.G |

B.W.G |

AS.W.G |

|

1G |

|

|

7.52 |

7.19 |

|

2G |

|

|

7.21 |

6.67 |

|

3G |

|

|

6.58 |

6.19 |

|

4G |

|

|

6.05 |

5.72 |

|

5G |

|

|

5.59 |

5.26 |

|

6G |

5.00 |

4.88 |

5.16 |

4.88 |

|

7G |

4.50 |

4.47 |

4.57 |

4.50 |

|

8G |

4.10 |

4.06 |

4.19 |

4.12 |

|

9G |

3.70 |

3.66 |

3.76 |

3.77 |

|

10G |

3.40 |

3.25 |

3.40 |

3.43 |

|

11G |

3.10 |

2.95 |

2.05 |

3.06 |

|

12G |

2.80 |

2.64 |

2.77 |

2.68 |

|

13G |

2.50 |

2.34 |

2.41 |

2.32 |

|

14G |

2.00 |

2.03 |

2.11 |

2.03 |

|

15G |

1.80 |

1.83 |

1.83 |

1.83 |

|

16G |

1.60 |

1.63 |

1.65 |

1.58 |

|

17G |

1.40 |

1.42 |

1.47 |

1.37 |

|

18G |

1.20 |

1.22 |

1.25 |

1.21 |

|

19G |

1.10 |

1.02 |

1.07 |

1.04 |

|

20G |

1.00 |

0.91 |

0.89 |

0.88 |

|

21G |

0.90 |

0.81 |

0.81 |

0.81 |

|

22G |

|

0.71 |

0.71 |

0.73 |

|

23G |

|

0.61 |

0.63 |

0.66 |

|

24G |

|

0.56 |

0.56 |

0.58 |

|

25G |

|

0.51 |

0.51 |

0.52 |

Custom Design Nails

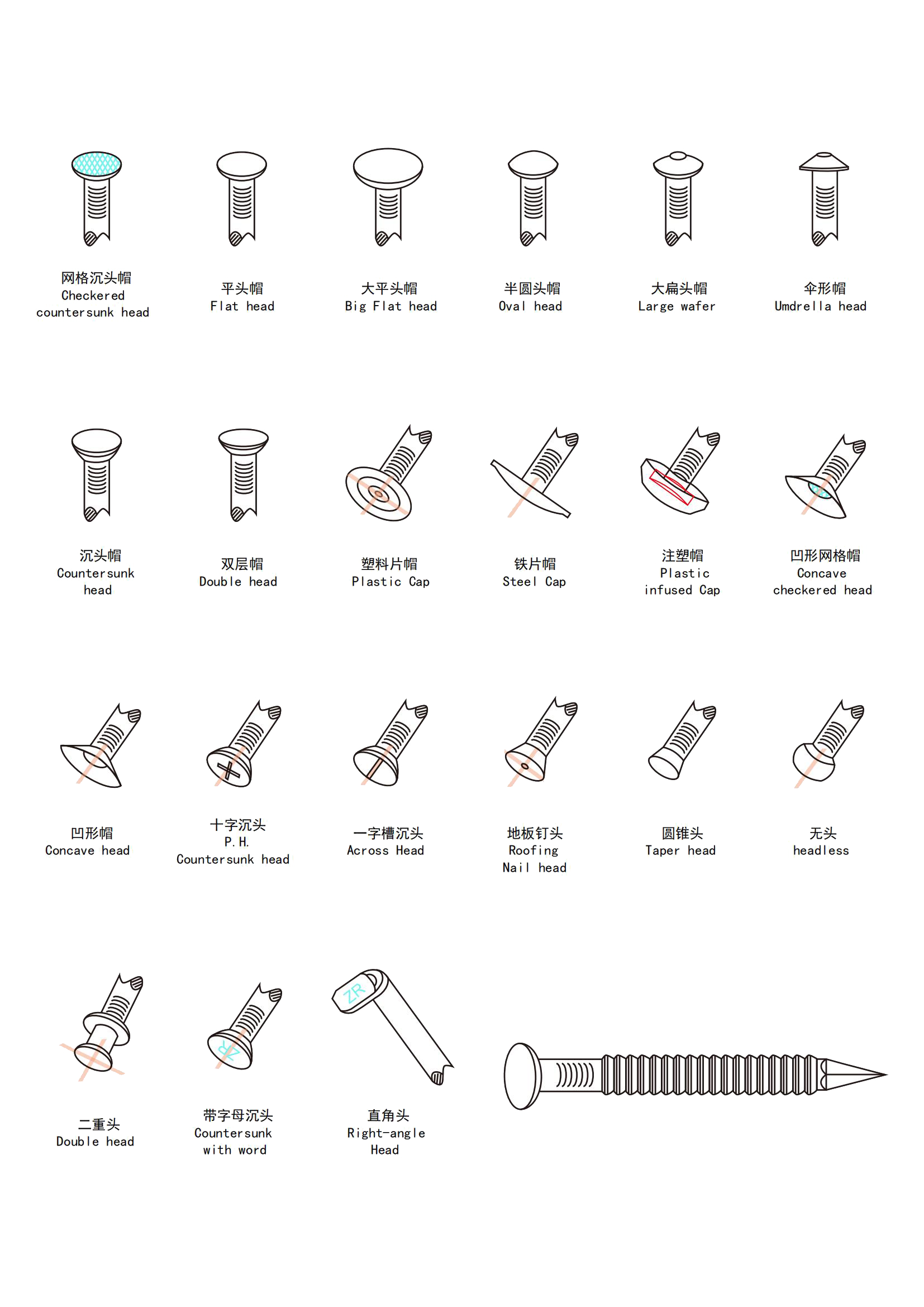

Type and Shape of Nails Head

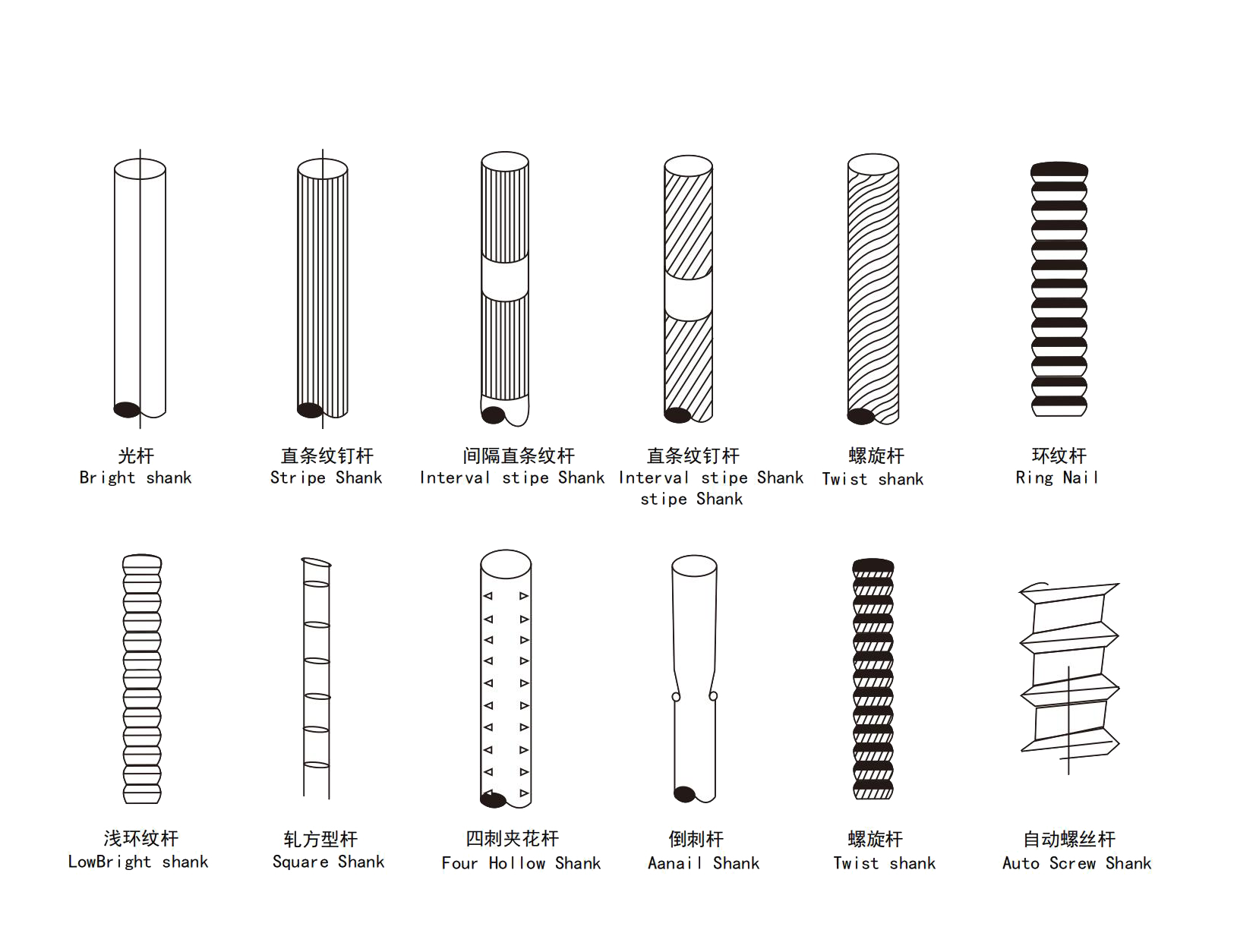

Type and Shape of Nails Shank

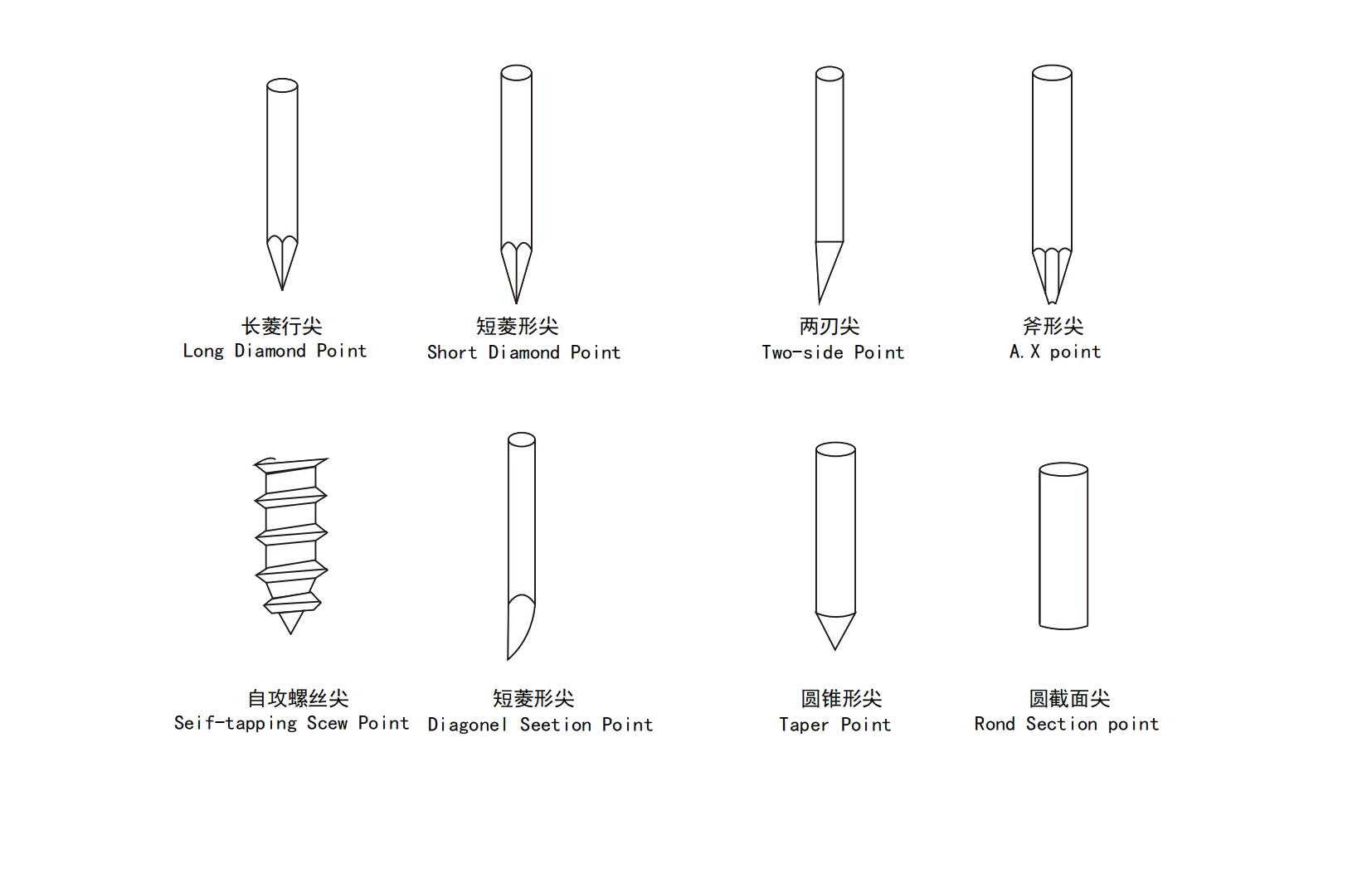

Type and Shape of Nails Point