countersunk stainless steel wood screw

Application

Countersunk stainless steel wood screws offer a wide array of applications across various industries. Some of the common applications include:

1. Woodworking and Cabinetry: These screws are widely used in furniture-making, cabinetry, and home improvement projects. With their flush finish and added strength, they securely hold wooden panels, joints, and frames together.

2. Marine Construction: The stainless steel composition of these screws makes them highly resistant to corrosion caused by saltwater exposure, making them ideal for marine construction, boat building, and repairs.

3. Outdoor Structures: Countersunk stainless steel wood screws are perfect for outdoor structures such as decking, timber cladding, and fences. Their durability and resistance to weathering allow them to withstand the elements and maintain structural integrity for years.

4. General Construction: From framing to installing subfloors, these screws provide reliable fastening for a wide range of general construction applications, including residential and commercial projects.

Feature

1. Superior Durability: The countersunk stainless steel wood screws are manufactured using premium-grade stainless steel, ensuring exceptional durability and resistance to corrosion, rust, and staining. This longevity guarantees that your projects remain structurally sound even in challenging environments.

2. Easy Installation: The conical shape of the countersunk head allows for easy insertion into pre-drilled holes. This design ensures a flush, professional finish, enhancing the aesthetic appeal of your woodwork.

3. Enhanced Performance: The screws' deep and sharp threads ensure a secure grip within the wood, reducing the risk of loosening over time. This feature guarantees a long-lasting and reliable connection, providing peace of mind for both professionals and DIY enthusiasts.

4. Versatility: Countersunk stainless steel wood screws come in various sizes and lengths, accommodating different wood types and thicknesses. This versatility allows for efficient fastening in a wide range of applications, eliminating the need for multiple screw options.

Plating

PL: PLAIN

YZ: YELLOW ZINC

ZN: ZINC

KP: BLACK PHOSPHATED

BP: GREY PHOSPHATED

BZ: BLACK ZINC

BO: BLACK OXIDE

DC: DACROTIZED

RS: RUSPERT

XY: XYLAN

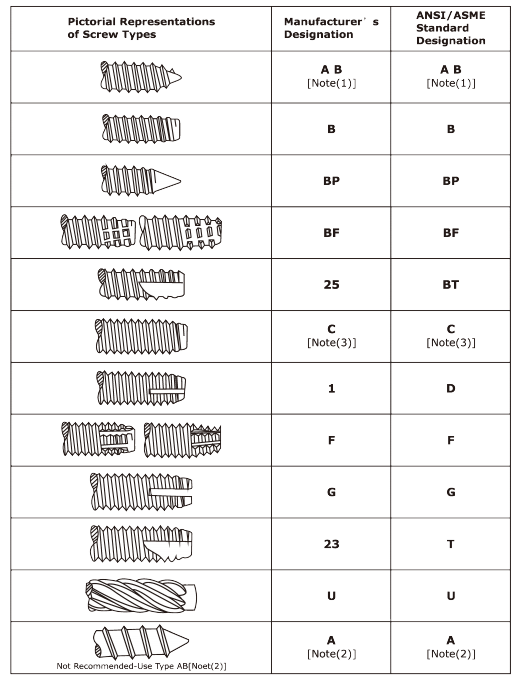

Pictorial Representations of Screw Types

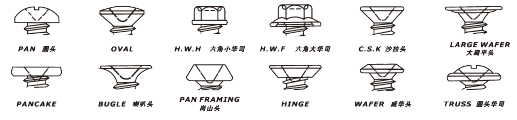

Head Styles

Head Recess

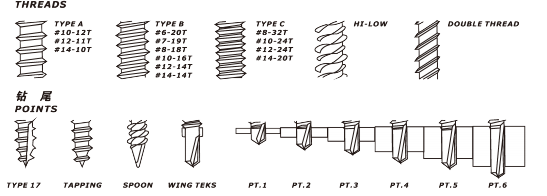

Threads

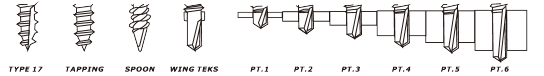

Points