Bright Pan Head Machine Screws

Application

Bright pan head machine screws find immense popularity in a multitude of applications across various industries. Their versatile characteristics make them suitable for both industrial and domestic uses.

In the industrial landscape, these screws are widely utilized in machinery, equipment manufacture, and assembly processes. They are instrumental in securing electrical enclosures, control panels, and switchboards, thereby ensuring the safety and integrity of electrical systems. Additionally, they find crucial applications in the automotive industry, where they are used to fasten components like brackets, panels, and bodywork.

Bright pan head machine screws also serve domestic purposes, as they are the go-to choice for DIY enthusiasts, contractors, and homeowners. From fixing appliances, furniture, and cabinetry to assembling electronics and projects, these screws provide a reliable and efficient fastening solution. The bright pan head machine screws’ distinct appearance also makes them a preferred choice for decorative purposes, such as attaching nameplates, signs, or accessories.

Feature

1. Versatility: These screws can be utilized in different materials like metal, wood, plastic, or fiberglass, expanding their application possibilities.

2. Easy Installation: With their Phillips drive, installing bright pan head machine screws is incredibly convenient. The standard Phillips screwdriver offers a widespread availability, making these screws easily accessible for anyone.

3. Secure Fastening: Thanks to their sturdy construction and durable material, these screws ensure a strong and tight connection, enhancing the overall stability of the assembled components.

4. Aesthetically Pleasing: The bright finish of these screws adds a touch of elegance and professionalism to the applications they are used in. This feature is especially beneficial when visibility of the fasteners is desired.

5. Corrosion Resistance: Bright pan head machine screws are often coated with anti-corrosion finishes, providing protection against rust and other forms of degradation, thus increasing their lifespan and reliability.

Plating

PL: PLAIN

YZ: YELLOW ZINC

ZN: ZINC

KP: BLACK PHOSPHATED

BP: GREY PHOSPHATED

BZ: BLACK ZINC

BO: BLACK OXIDE

DC: DACROTIZED

RS: RUSPERT

XY: XYLAN

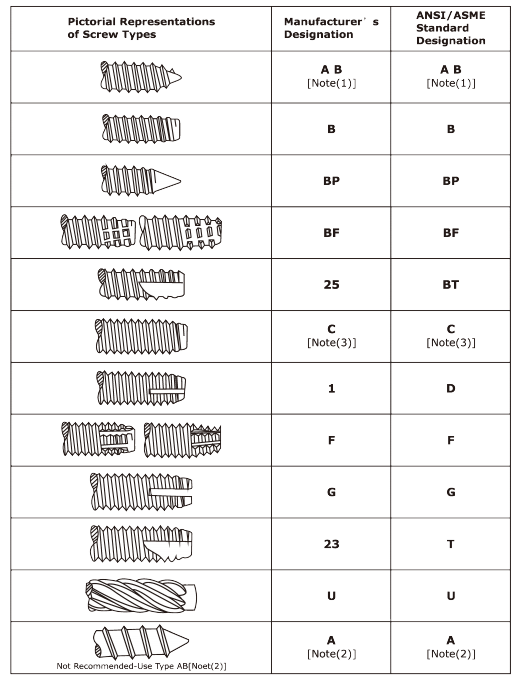

Pictorial Representations of Screw Types

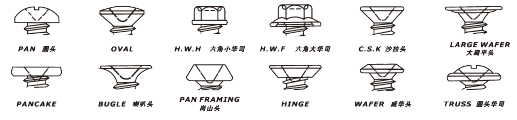

Head Styles

Head Recess

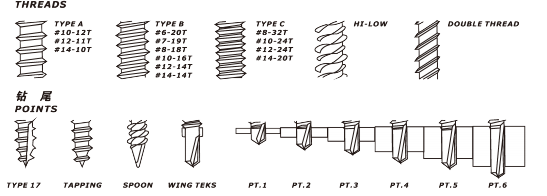

Threads

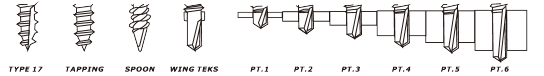

Points